Visualizing Asia’s Dominance in the Titanium Supply Chain

Asia’s Dominance in the Titanium Supply Chain

Titanium is a unique metal with important applications in defense, aerospace, automotives, and medicine.

But before making it into all its end uses, titanium goes through a complex supply chain that involves both geopolitical and environmental challenges.

This infographic sponsored by IperionX explores the titanium supply chain and highlights the countries that dominate it.

The Stages of Titanium Production

Titanium’s end-to-end production process typically involves five steps:

- Mineral extraction

The minerals ilmenite and rutile are the primary feedstocks for titanium production. These minerals are partly composed of titanium dioxide, which is later refined into titanium metal.

- Sponge metal production

Ilmenite and rutile are refined into titanium sponge using the Kroll refining process. - Ingots and melted products

Titanium sponge is melted into ingots and other melted products. - Mill products

Finished products like bars, sheets, and tubes are manufactured from ingots. This process typically generates large amounts of machining scrap. - Scrap

Scrap or waste accounts for large material losses in the supply chain. The current scrap recirculation rate is less than 70%.

The Kroll process of refining titanium minerals to produce sponge metal is an 80-year-old method that involves high energy use and carbon emissions. It’s also heavily dependent on a few countries, primarily in Asia.

The Titanium Supply Chain

The mineral ilmenite accounts for 90% of all titanium mineral consumption. The other feedstock, rutile, is only mined on a small scale.

Here’s a look at the 10 largest ilmenite and rutile producers in 2021:

| Country | 2021 titanium minerals production (tonnes of titanium dioxide content) | % of Total |

|---|---|---|

| China 🇨🇳 | 3,400,000 | 36% |

| Mozambique 🇲🇿 | 1,108,000 | 12% |

| South Africa 🇿🇦 | 995,000 | 10% |

| Australia 🇦🇺 | 790,000 | 8% |

| Canada 🇨🇦 | 430,000 | 5% |

| Norway 🇳🇴 | 468,000 | 5% |

| Ukraine 🇺🇦 | 411,000 | 4% |

| Senegal 🇸🇳 | 491,000 | 5% |

| Madagascar 🇲🇬 | 414,000 | 4% |

| Kenya 🇰🇪 | 253,000 | 3% |

| Other 🌍 | 740,000 | 8% |

| Total (rounded) | 9,500,000 | 100% |

China takes up the lion’s share of titanium mineral production at 36%. It produces three times as much of the minerals as Mozambique, the second-largest producer. Meanwhile, the U.S. is grouped with other countries with just 100,000 tonnes in annual production.

Besides titanium mineral extraction, China also dominates the next stage of the supply chain with 57% of global titanium sponge production:

| Country | Titanium sponge production (tonnes) | % of Total |

|---|---|---|

| China 🇨🇳 | 120,000 | 57% |

| Japan 🇯🇵 | 35,000 | 17% |

| Russia 🇷🇺 | 27,000 | 13% |

| Kazakhstan 🇰🇿 | 16,000 | 8% |

| Ukraine 🇺🇦 | 5,400 | 3% |

| Saudi Arabia 🇸🇦 | 3,700 | 2% |

| U.S.* 🇺🇸 | 500 | 0.20% |

| India 🇮🇳 | 250 | 0.10% |

| Total (rounded) | 210,000 | 100% |

*Represents production capacity for high purity specialty sponge, not available for commercial applications.

Between 2011 and 2021, China expanded its titanium sponge production capacity by 55%. Over the same period, U.S. production capacity almost declined completely, down 98%.

As a result of the lack of domestic production, the U.S. is now heavily reliant on foreign sources of titanium.

Short Supply: Titanium in the U.S.

Around 90% of U.S. titanium consumption is met by net imports, with most of it coming from Japan.

The U.S. uses titanium metal in various sectors, including defense, aerospace, electronics, and transport. With the demand for titanium projected to grow, a domestic titanium supply chain can help the U.S. become independent of imports.

IperionX is a U.S. metals technology company focused on developing the world’s first 100% recycled, low-cost, low-carbon titanium supply chain.

>>>Interested in learning more about IperionX’s titanium production technology? Click here to learn more now.

-

Markets3 weeks ago

Markets3 weeks agoHow Big is the Market for Crude Oil?

The oil market is bigger than the 10 largest metal markets combined, with production value exceeding $2 trillion annually.

-

Urbanization2 months ago

Urbanization2 months agoRanked: The World’s Biggest Steel Producers, by Country

China has dominated global steel production the past few decades, but how did the country get here, and is its production growth over?

-

Mining4 months ago

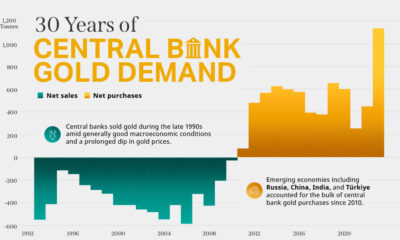

Mining4 months agoCharted: 30 Years of Central Bank Gold Demand

Globally, central banks bought a record 1,136 tonnes of gold in 2022. How has central bank gold demand changed over the last three decades?

-

Energy6 months ago

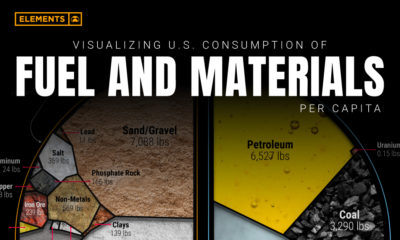

Energy6 months agoVisualizing U.S. Consumption of Fuel and Materials per Capita

Wealthy countries consume large amounts of natural resources per capita, and the U.S. is no exception. See how much is used per person.

-

Commodities6 months ago

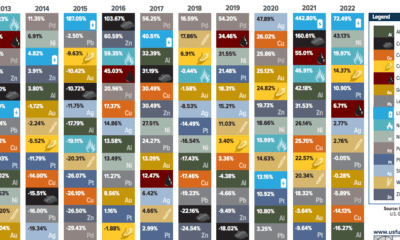

Commodities6 months agoThe Periodic Table of Commodity Returns (2013-2022)

This table shows the fluctuating returns for various commodities over the past decade, from energy fuels to industrial and precious metals.

-

Batteries7 months ago

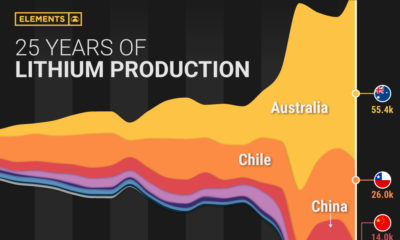

Batteries7 months agoVisualizing 25 Years of Lithium Production, by Country

Lithium production has grown exponentially over the last few decades. Which countries produce the most lithium, and how how has this mix evolved?