Modular Housing vs. Traditional Housing: How Do They Compare?

Modular Housing vs. Traditional Housing: How Do They Compare?

The U.S. needs new houses. Lots of them.

With housing prices nearing six times annual incomes, increasing supply is a must if there is any hope of bringing down house prices, and modular housing could be the solution.

This visualization is the third and final piece of the Reimagining Home Series from our sponsor Boxabl, where we compare the benefits of modular housing against traditional construction methods. Let’s start with the basics.

What Is Modular Housing?

Modular homes are built offsite, in standardized sections, usually in a factory setting. They are then transported to the building site and assembled on a waiting foundation. Once complete, modular homes look just like any other house.

Modular housing is not the same as manufactured homes, which are also sometimes called mobile homes. Like modular housing, manufactured homes are built offsite in a factory, but the key difference is that they can be moved after being assembled. Modular homes aren’t meant to be moved again after final assembly.

6 Ways Modular Homes Differ to Traditional Homes

The following benefits are based on information from the Modular Home Building Association, as well as a paper given at the 2020 Creative Construction e-Conference by members of the Department of Civil Engineering at the University of Texas at Arlington.

1. Speed of Construction

Because of the piecemeal nature of modular construction, many building activities can be done simultaneously, greatly reducing the overall time of completion. At the same time, because construction happens indoors, weather delays aren’t an issue. Overall, a modular housing project can be completed in 40% less time than using traditional building construction methods.

2. Cost Effectiveness

Standardization of design, less transportation of materials onsite, and the reduced impact of weather are some of the reasons that modular housing can be much cheaper than traditional building methods. According to the authors of the paper, there was a 10-25% decrease in construction costs for modular housing, again, compared to traditional methods.

3. Customizable

A common misconception is that modular housing isn’t customizable. While many manufacturers will often begin with a starter floor plan, they may also offer various customization options throughout the home.

4. Safety Record

Construction is a dangerous way to make a living. In 2021, construction and extraction workers held the number two spot for fatal occupational injuries in the U.S., with 951 work fatalities.

When you drill down into that number, construction tradespeople are in the majority, by far, with 726 that year alone.| Description | Fatalities |

|---|---|

| Transportation and material moving occupations | 1,523 |

| Construction and extraction occupations | 951 |

| Installation, maintenance, and repair occupations | 475 |

| Building and grounds cleaning and maintenance occupations | 356 |

| Management occupations | 323 |

| Protective service occupations | 302 |

| Production occupations | 242 |

| Farming, fishing, and forestry occupations | 218 |

| Sales and related occupations | 200 |

| Food preparation and serving related occupations | 101 |

| Office and administrative support occupations | 91 |

| Unknown occupation | 71 |

| Personal care and service occupations | 64 |

| Healthcare practitioners and technical occupations | 57 |

| Arts, design, entertainment, sports, and media occupations | 45 |

| Community and social services occupations | 40 |

| Healthcare support occupations | 32 |

| Architecture and engineering occupations | 29 |

| Business and financial operations occupations | 27 |

| Educational instruction and library occupations | 16 |

| Legal occupations | 11 |

| Life, physical, and social science occupations | 10 |

| Computer and mathematical occupations | 6 |

| Military occupations | 0 |

| Total | 5,190 |

Because modular construction happens in a controlled, factory environment, the number of accidents decreases by 80% compared to traditional building methods.

5. Environmental Impact

Anyone who has walked past a residential build site can testify to the amount of waste produced during construction. Modular construction is more efficient and therefore produces less waste. And because onsite construction is limited to assembly, there is less dust and noise. Carbon emissions are also 38% lower.

6. Built to Last

Modular housing is as good, if not better constructed, than many traditionally-built houses. The factory environment allows for superior quality control, and homes built this way use 15-20% more wood per square foot, which makes them stronger. Moreover, in a study commissioned by the Federal Emergency Management Agency after 1992’s Hurricane Andrew found that modular housing “performed much better than conventional residential framing.”

A Market On The Rise

Not only is modular housing cheaper and greener than traditional construction methods, it is also a market on the rise.

According to a recent report, the global modular construction market is expected to reach $54 billion by 2027, with a CAGR of 2.9% between 2021 to 2027.

Thinking Outside of the Box on Housing

Modular housing could be a solution to the housing affordability crisis not only in the U.S., but around the world. And with the global city population expected to hit 68% by 2050, it’s time to think outside the box on housing.

Boxabl uses advanced, mass production techniques to build and ship homes that significantly lower the cost of home ownership for everyone.

This is the final piece in the Reimagining Home Series from our sponsor, Boxabl. Be sure to read parts one and two on urbanization and affordable housing.

Learn more about how Boxabl is helping tackle the housing affordability crisis.

-

Markets2 weeks ago

Markets2 weeks agoVisualizing 1 Billion Square Feet of Empty Office Space

Empty office space is hitting record highs in 2023. We show almost 1 billion square feet of unused space stacked as a single office tower.

-

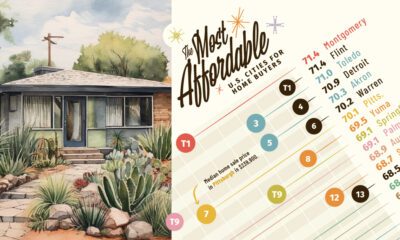

Money1 month ago

Money1 month agoRanked: The Most Affordable U.S. Cities for Home Buyers

There’s more to consider than the price tag when purchasing a house. This ranking reveals the most affordable U.S. cities for home buyers.

-

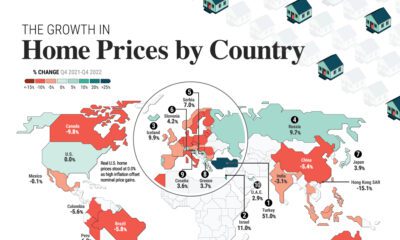

Markets1 month ago

Markets1 month agoMapped: The Growth in House Prices by Country

Global house prices were resilient in 2022, rising 6%. We compare nominal and real price growth by country as interest rates surged.

-

Money5 months ago

Money5 months agoVisualized: The Most (and Least) Expensive Cities to Live In

From New York to Damascus, this infographic uses EIU cost of living data to rank the world’s most and least expensive cities to live in

-

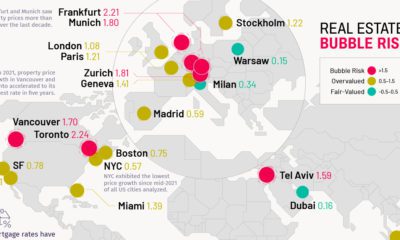

Markets9 months ago

Markets9 months agoThese Global Cities Show the Highest Real Estate Bubble Risk

A global look at which cities have the most overheated real estate markets. Toronto shows the highest bubble risk in 2022.

-

Real Estate12 months ago

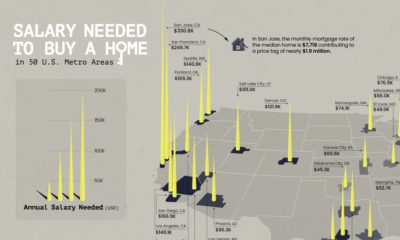

Real Estate12 months agoMapped: The Salary You Need to Buy a Home in 50 U.S. Cities

Is owning a home still realistic? This map lays out the salary you’d need to buy a home in 50 different U.S. metro areas.